UN approved drums are available in a range of sizes, materials and opening configurations to meet the diverse needs of businesses handling dangerous goods. Here are some common types:

- Steel Drums 1A1/1A2: Steel drums are known for their strength and durability. They are often used for transporting compatible flammable liquids, chemicals, and other hazardous substances. UN approved Steel drums are available with 1A1 – non removable heads or 1A2 removable heads.

- Aluminium Drums 1B1/1B2: UN approved aluminium drums are also available with 1A1 – non removable heads or 1A2 removable heads. These drums must be constructed of aluminium at least 99% pure or of an aluminium base alloy. They are lighter in weight than the equivalent steel drum, offering an advantage of lower transport costs and easier manual lifting/handling.

- Plastic Drums 1H1/1H2: Plastic drums, typically made from high-density polyethylene (HDPE), offer excellent chemical resistance and are suitable for a wide range of hazardous substances. They are lightweight, easy to handle, and cost-effective.

- Fibre Drums 1G: Fibre drums are constructed using multiple plies of heavy paper (e.g.Kraft paper) or fibreboard, glued or laminated together. Typically, UN approved fibre drums are approved for solid and granular materials. They are lightweight and stackable.

- Composite Drums: 6HA1/6HA2 composite steel drums consist of a plastic receptacle with a steel outer drum. Benefits include the strength and durability of a steel drum, plus the chemical compatibility of a polyethylene drum.

Shippers must check compatibility of the substance with the drum material to ensure suitability.

How to choose the right UN approved drum for your needs

Choosing the right UN approved drum is essential to ensure the safe and compliant transport of dangerous goods. Here are some factors to consider when selecting a drum:

- Compatibility: Ensure the drum is compatible with the specific hazardous substance you are transporting. Do you require a lacquer lined or plain drum? Consider factors such as chemical compatibility, storage temperature requirements, and the material’s corrosive properties.

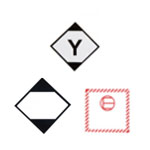

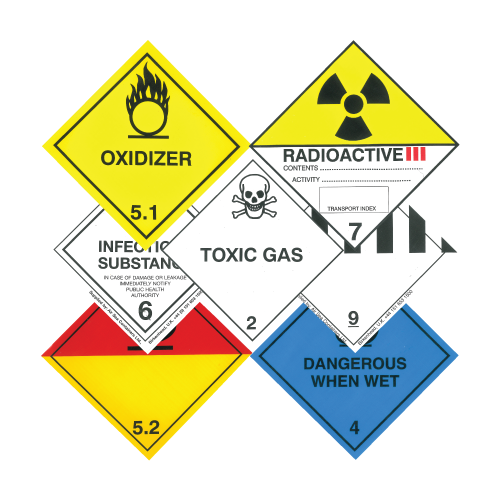

- Packing Group (PG): Each UN approved drum will have been tested to be used with PG I (X), II (Y) or III (Z). Substances are assigned to the relevant packing group according to the degree of danger they present. Roman numerals I, II and III are used to represent “high danger”, “medium danger” and “low danger” respectively. The drum must be approved for use with the PG assigned to the dangerous goods.

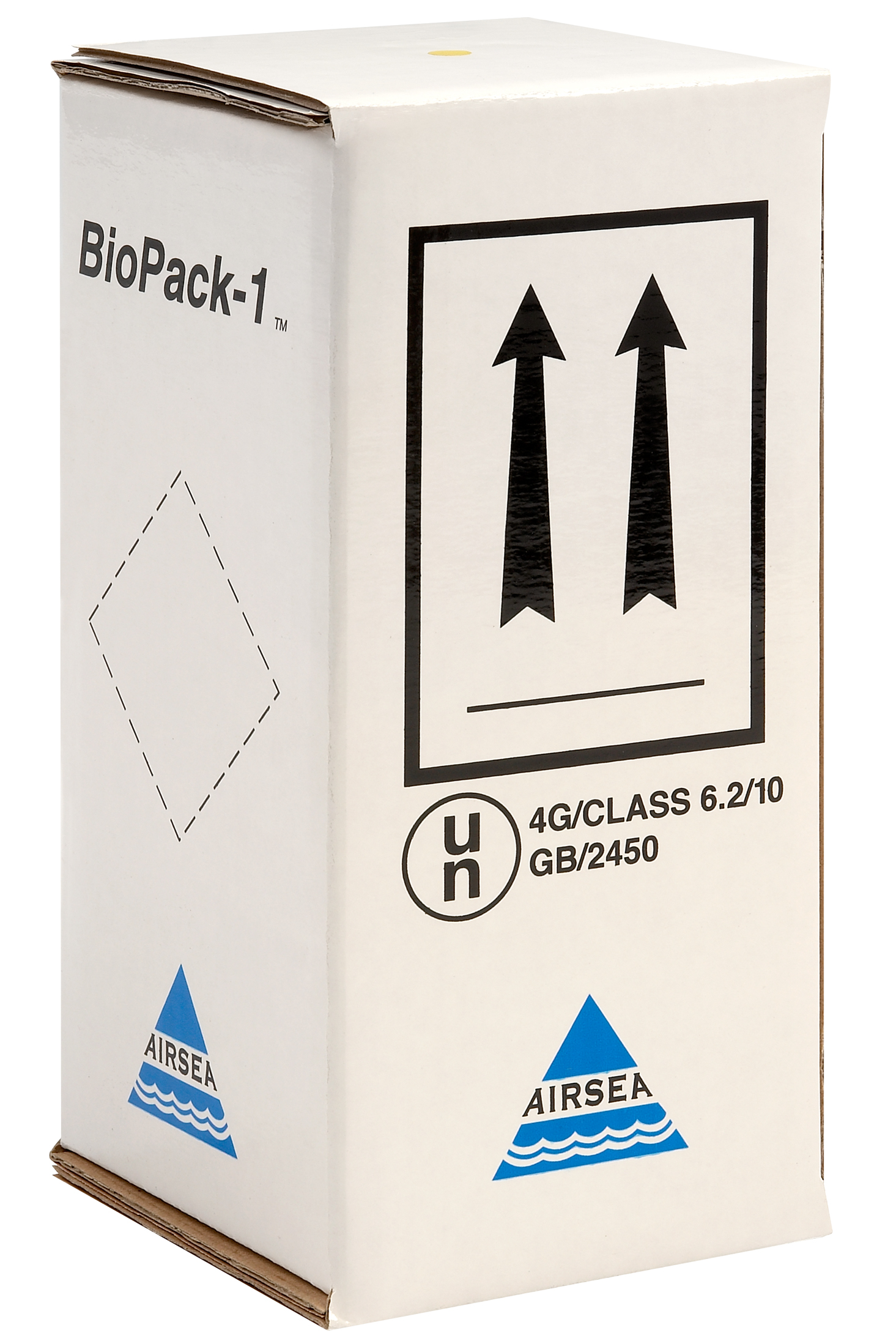

- Is the dangerous goods a Solid or Liquid?: Consider the state of matter. Each UN drum is approved for either solids or liquids, or in some cases has been tested for both (the drum will display two separate UN marks). The UN mark displayed on the drum indicates if the drum has been tested for Liquids or Solids. Liquid density and the pressure capability must also be considered for liquids. You can read more about UN Marks here.

- Capacity: Determine the required capacity based on the volume of hazardous substances you need to transport. Consider factors such as brim fill, density (liquids), weight restrictions, and the availability of appropriate drum sizes.

- Closure Mechanism: Evaluate the closure mechanism of the drum. Depending on the hazardous substances being transported would 1A1 non removable heads or 1A2 removable heads be more suitable? Open tops (removable heads) are often used for articles, solids and granular materials, whilst closed tops (non removable heads) work well with liquids. Lids must also provide a secure and leakproof seal, consider the different closure types, such as bungs, bolted rings or lever-lock closures.

- Testing and Certification: Check for a UN mark on the drum, this indicates that it has been tested and approved for the transportation of (suitable) dangerous goods. The UN mark identifies several tests the drum has passed and explains the design and capability of the drum. A UN mark reassures shippers that the drum meets the specific test requirements set out in the transport of dangerous goods regulations for UN approved drums.

- Additional Features: Consider any additional features that may be required for your specific needs, such as ease of handling (handles, spouts, taps), tamper-evident closures. Weight of drum for shipping costs and manual handling ease. Whether lacquer lined, plain or a liner bag is required and temperature fluctuations during transport.

Packing Instructions (PI):

Packaging Instructions within the relevant mode of transport regulations provide the shipper instructions of how to package the dangerous goods compliantly. To abide by the UN transport regulations, shippers must refer to the packing instructions relating to the dangerous goods to identify the appropriate types of packaging and other applicable requirements indicated in the PI such as:

- Maximum quantity

- Types of packaging

- Closure requirements

- PG performance requirements

- Compatibility requirements

For more information on what packaging is suitable for your dangerous goods you can speak to one of our advisers.

UK

UK