In this article we discuss why it is so important to assemble UN packaging correctly.

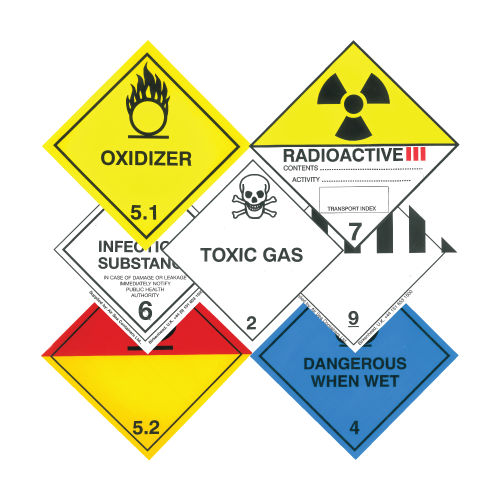

UN Approved Packaging has been designed, tested and certified to enable the safe transportation of Dangerous Goods via road, sea, rail or air.

Its purpose is to prevent and subsequently contain a leak or exposure should the substance/article or the packaging become compromised during transport.

Typically, UN approved packaging tends be referred to as either combination packaging or single packaging. Combination packaging is an UN Approved Outer packaging and within that would be the inner receptacles or inner packaging, as well as any absorbent or cushioning material to protect the inner(s). Single packaging are packagings that do not require any inner packaging in order to perform their containment function during transport.

In order for a package design to become UN Approved, the packaging itself has to pass rigorous tests specified in the relevant DG regulations. The manufacturer designing the packaging must adhere to strict guidelines regarding packaging specification and ensure the packaging passes a number of tests to prove it is capable of withstanding normal conditions of transport.

The transport of dangerous goods is subject to strict regulations, it is the shipper’s responsibility to ensure that such regulations are adhered to and packaging requirements are met when transporting dangerous goods by air, sea, rail and road. However, compliance doesn’t just stop there . It is important to remember that once the correct UN packaging has been chosen, the shipper must assemble it as per the manufacturer’s instructions in order for the packaging to perform to its capability. If incorrectly assembled you risk invalidating the UN test certificate and could compromise the capability of the packaging.

Assembly errors that can render the test certification invalid.

Using incorrect inners for a 4G box

Each 4G packaging design has been tested and approved with the use of specific inner packaging. So, you cannot use any type of inners in your 4G box. For instance, if your chosen 4G box was tested and approved with 4 x 250ml plastic bottles, you cannot pack it with 2 x 500ml plastic bottles or 4 x 250ml glass bottles. The packaging was not designed to carry these types of inners and therefore has not been tested or approved for their use.

Incorrect weight limits of inners

4G and 4GV or 4DV packaging have different rules when it comes to weight allowance. In the case of 4G packaging, the number stated in the UN Mark corresponds to the maximum gross mass in kilograms, at which the design type has been tested. In this example the ‘16’ in the UN Mark 4G/X16/S/22/ refers to the maximum gross mass in kilograms of the entire package (inners, substances and other accessories like cushioning materials).

Whilst the UN Mark on “V” variants also states the maximum gross mass in kilograms, the gross mass of inner packagings should not exceed one-half the gross mass of inner packaging used for the drop test. Basically, this means that only half the weight of the tested inners are allowed for the said 4GV or 4DV packaging design.

Shippers can refer to the assembly sheet that accompanies the packaging for inner packaging weight allowances.

Using incorrect cushioning.

Shippers cannot choose their preferred cushioning type in the UN approved packaging. As each UN approved packaging design has undergone rigorous test in order for it to prove its capabilities and to gain UN certification, the cushioning used in the tests needs to be the same cushioning type when assembling the UN packaging. For example, if it’s been tested with vermiculite, then you must use vermiculite, if alternative cushioning is used, not only will it invalidate the UN certification but you also risk the inners and substances being compromised during transit.

Removing buffers or partitioning

It has been known for shippers to remove buffers and partitions to accommodate their own inners. Again, tests are undertaken to ensure the packaging design can withstand various factors that may be experienced during transport. If you remove or change the buffering or partitions, you remove the support and the protection these provide and will compromise the integrity of your package and its capability to protect the inners and substance. If these are removed, the UN packaging is therefore not being used as per its design approval, so the UN approval certification will no longer be valid.

Incorrect tape of taping method being applied

If the tape or taping method used isn’t same type applied in the testing process, the shipper could compromise the sealant strength and structural support of the packaging. Less robust tape could result in the tape adhesive not being strong enough to adhere to the packaging, whilst using a different taping method could result in the packaging top flaps or bottom flaps opening during transport.

The importance of following the assembly sheet

It is fundamental to refer to relevant transport regulation to ascertain the correct packaging requirements for your dangerous goods, however, the packing process is also important and one often over looked. Ensuring the packing process is done compliantly and the substance is packed correctly as per the assembly instructions is fundamental in ensuring that the box can fulfil its capabilities. If this step is overlooked, the shipper could inadvertently pack the dangerous goods incorrectly which could end up invalidating the UN certification and therefore it would not be packed compliantly nor safely.

Air Sea USA is passionate about shippers using our products correctly that’s why we provide assembly instructions as standard with all our combination packaging. To make the process even easier, assembly instructions are instantly accessible via assembly QR Codes printed on our newly branded combination boxes.

If you require any assistance choosing the right packaging or for more information on the correct assembly, get in touch, our trained advisors are here to help.

Don’t get caught out by assembling your packaging Incorrectly alwayshttps://www.airseadg.com/contact/ follow the manufacturers assembly instructions.

US

US