Sample Pack – UN 4G Box for various inners, 4G/X2/S

Internal Dimensions: 2.76" x 2.76" x 6.89"

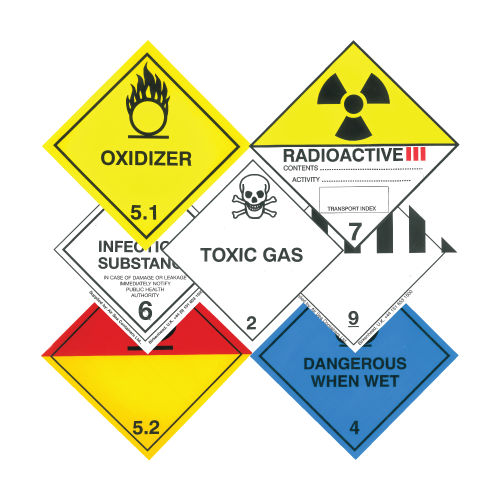

UN 4G box for 1 x 5L UN steel drum with flammable Liquid Hazard Label, 4G/X15/S

Internal Dimensions: 8.27" x 8.27" x 8.86"

UN 4G Fibreboard box for 1 x 5L Jerrican, 4G/X12/S

Internal Dimensions: 7.55" x 5.66" x 10.39"

UN 4G Fibreboard box for various inners, 4G/X15/S

Internal Dimensions: 7.65" x 5.71" x 12.4"

US

US