The UN Mark on UN approved packaging provides the user information about the packaging type, the packaging material, the packing group and the gross weight, so it’s pretty straight forward to identify the maximum weight for your 4G packaging, right?

Ok so what about a 4GV box, how much hazardous goods can you put in a 4GV box? Good question…

If you think it’s the full weight shown on the UN Mark you’d be wrong.

The Rules Explained

First let’s start with 4G packaging.

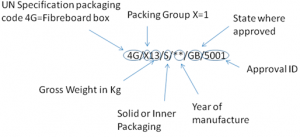

A UN mark identifies that a packaging has been approved to United Nations standards for the transport of hazardous goods by road, sea and/or air. A UN mark will usually be made up of a number of numbers and letters, directly following a ‘UN’ logo. Below is an example of a UN mark that would be displayed on an approved fibreboard box – known as a 4G package.

When looking for the maximum gross weight of a 4G box, most of us would refer to the UN Mark. Let’s use the above UN Mark as an example for a 4G packaging 4G/X13/S/20/GB/5001.

So, in this example the ‘13’ in the UN Mark 4G/X13/S/20/GB/5001 refers to the maximum gross mass in kilograms of the entire package.

The UN Recommendations on the Transport of Dangerous Goods Model Regulations (UNRTDG) states for packagings intended to contain solids or inner packagings this is the number corresponding to the maximum gross mass in kilograms, at which the design type has been tested.

However, when you add the letter “V” to the packaging code (4GV) this signifies a “Special Packaging” conforming to an additional set of requirements.

4GV Weight Rules

What does the “V” stand for and what are its special set of requirements relating to weight?

UNRTDG regulations states one of the special packaging requirements relating to weight for “V” variants is ‘the total combined gross mass of inner packagings shall not exceed one-half the gross mass of inner packaging used for the drop test’.

Simplified, it is actually only half the weight of the tested inners. So how are you meant to know what that figure is? Well, you’d really need to look at the test certificate or refer to the assembly sheet that comes with the 4GV packaging in question. Upon purchase, all reputable packaging suppliers should provide you with an assembly sheet that gives clear instructions of how to correctly assemble and pack your hazardous goods within the specified packaging. It is imperative that the hazardous goods are packed the exact same way that the packaging was tested for. UN approved packaging used incorrectly will invalidate the performance certification, this stage in the packing process is often overlooked.

If shippers ignore the weight restrictions applied when using 4GV packaging, both the inner and outer packaging could be put under undue stress and strain resulting in the packaging succumbing to excessive pressure or indeed leakage when the package is handled under normal conditions of transport. Ultimately by doing this you will invalidate the approval.

So, remember when purchasing 4GV packaging ask the supplier for an assembly sheet so you can ensure you are shipping within the allowed weight.

US

US