As the world becomes more environmentally conscious, many businesses are looking for ways to reduce their carbon footprint. One way to do this is by using biodegradable products, such as packing chips. In this brief guide, we explore the benefits of biodegradable packing chips, how they work, and how to dispose of them properly.

Introduction to Biodegradable Packing Chips

Packing chips are a popular way to protect items during shipping. They are small, lightweight, and fill the empty space in boxes to prevent items from moving around. However, traditional packing chips are made from materials that are not biodegradable, such as polystyrene foam. These materials can take hundreds of years to break down, creating a significant environmental impact.

Biodegradable packing chips, on the other hand, are made from materials that can decompose naturally over time. This makes them a more sustainable option for businesses that want to reduce their environmental impact.

What Does Biodegradable Mean?

The term “biodegradable” refers to the ability of a material to break down into natural substances over time. Biodegradable products can be broken down by microorganisms, such as bacteria and fungi, into carbon dioxide, water, and other natural substances. This process is known as biodegradation.

In contrast, non-biodegradable products, such as traditional packing chips, do not decompose naturally and can take hundreds of years to break down. This creates a significant environmental impact and contributes to the growing problem of plastic pollution.

The Importance of Using Biodegradable Products

Using biodegradable products is an important way to reduce our impact on the environment. When non-biodegradable materials are disposed of improperly, they can end up in landfills or the ocean. This creates pollution and harms wildlife.

Biodegradable products, such as packing chips, can help to reduce this pollution by breaking down naturally over time. This reduces the amount of waste that ends up in landfills and the ocean, helping to protect the environment and wildlife.

Types of Biodegradable Packing Chips

There are several types of biodegradable packing chips available, each made from different materials. Some of the most common types of biodegradable packing chips include:

Starch-Based Packing Chips

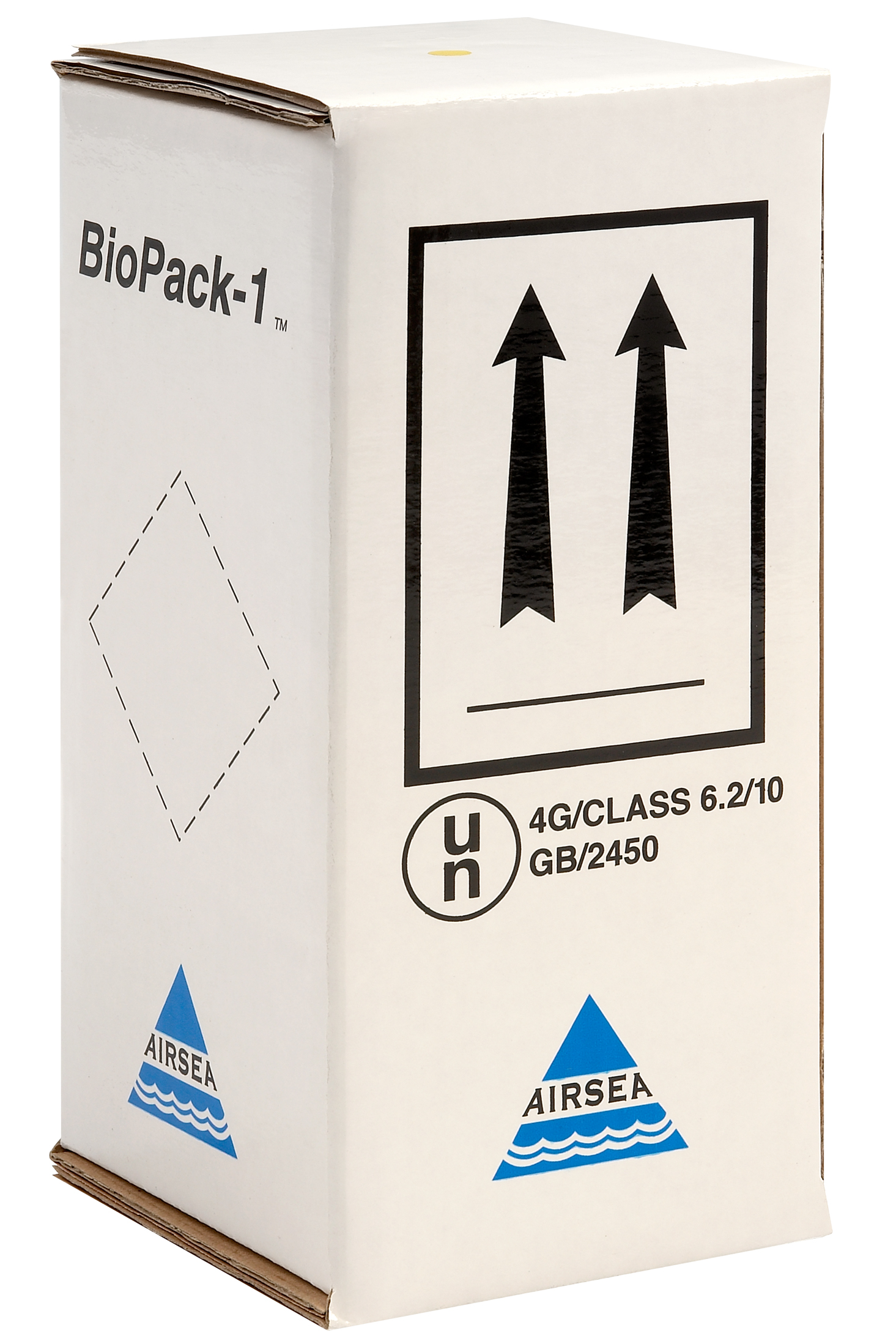

Starch-based packing chips are made from corn starch or potato starch. They are completely biodegradable and can be composted in a home composting system. These chips are also water-soluble, making them easy to dispose of. Air Sea Containers use corn starch chips in their 4GV packaging as an alternative to the traditional dangerous goods cushioning, vermiculite. These white odourless chips are a lightweight and dust-free alternative to Vermiculite and provide shock and impact protection to inner packagings during transport.

Mushroom-Based Packing Chips

Mushroom-based packing chips are made from mycelium, the root structure of mushrooms. They are completely biodegradable, non-toxic and can be composted in a home composting system.

How do Biodegradable Packing Chips Work?

Biodegradable packing chips work by breaking down naturally over time. When exposed to microorganisms, such as bacteria and fungi, the chips begin to decompose, eventually breaking down into carbon dioxide, water, and other natural substances.

This process can take anywhere from a few weeks to several months, depending on the type of biodegradable packing chips and the conditions they are exposed to. In general, biodegradable packing chips require moisture, warmth, and oxygen to decompose properly.

Advantages of Using Biodegradable Packing Chips

There are several advantages to using biodegradable packing chips, including:

Reduced Environmental Impact

Biodegradable packing chips have a significantly reduced environmental impact compared to traditional packing chips. They break down naturally over time, reducing the amount of waste that ends up in landfills and the ocean.

Sustainable

Biodegradable packing chips are made from sustainable materials, such as corn starch, mycelium and potato starch. This makes them a more eco-friendly option for businesses that want to reduce their carbon footprint.

Easy to Dispose of

Biodegradable packing chips are easy to dispose of. They can be composted in a composting system, or some you can simply put in water and they will break down. This makes them a convenient option for businesses.

The Future of Biodegradable Packing Chips

As businesses become more environmentally conscious, the demand for biodegradable packing chips is expected to increase. This will drive innovation and the development of new, eco-friendly materials for packaging.

In addition, governments around the world are implementing regulations to reduce plastic pollution and encourage the use of biodegradable products. This will further drive the adoption of biodegradable packing chips and other sustainable packaging options.

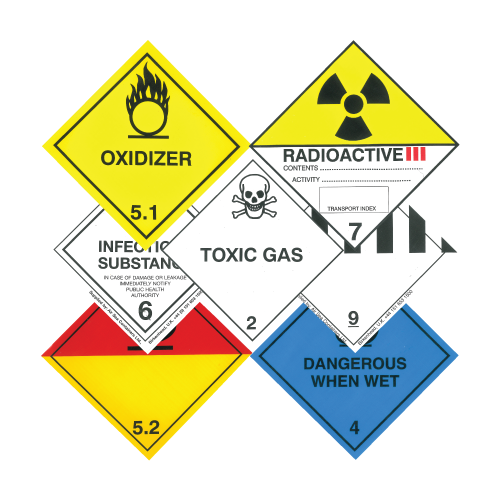

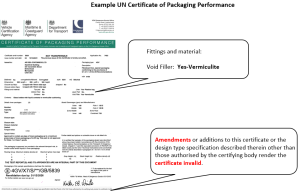

Caution

Take care when using UN approved packaging, for example, 4G and 4GV fibreboard box approvals will specifically detail what type of packaging fill has been used to pass the relevant tests. This can differ and is a good reason why users of packaging must obtain manufacturers assembly instructions prior to use. Using the incorrect packaging material will invalidate the UN approval.

Conclusion

Biodegradable packing chips are a more sustainable option for businesses that want to reduce their environmental impact or require a dust-free alternative to vermiculite when used in dangerous goods packaging. They are made from eco-friendly materials, break down naturally over time and are easy to dispose of. However, do consult with your packaging manufacturer and check what specific packaging fill materials have been approved with any UN approved packaging first.

Contact Air Sea Containers for more information and guidance on Dangerous Good Packaging or for more information on Biodegradable packing.

Information correct at time of publishing, 26th June 2023

UK

UK