When it comes to shipping Dangerous Goods, safety is paramount, that’s why strict regulations were established by the Economic and Social Council (ECOSOC) Committee of Experts on the Transport of Dangerous Goods for packaging dangerous goods. UN approved packaging ensures that dangerous goods are properly contained and transported without the risk of leakage, spills, or contamination, but how much do you know about the different types of UN approved packaging?

From drums to boxes, bottles to jerricans, UN approved packaging comes in various forms, all of which must meet the specific requirements of dangerous goods regulations. Each type of UN approved packaging is rigorously tested and certified to comply with the applicable UN dangerous goods transport regulations, ensuring the safe shipment of dangerous goods around the world.

In this article, we will explore the main types of UN approved packaging and their features. Whether you are shipping articles, chemicals, pharmaceuticals or flammable liquids, understanding the different packaging options available will help you maintain compliance and keep your shipments safe.

Why is UN approved packaging important?

UN approved packaging plays a crucial role in the safe transportation of dangerous goods.

One of the main reasons why UN approved packaging is essential is the prevention of leakage or spillage. The packaging undergoes rigorous testing to ensure it can withstand the conditions it may encounter during transportation, such as temperature changes, shock, vibrations, and pressure. This ensures that hazardous materials remain securely contained, reducing the risk of breakage, spills and contamination during transit.

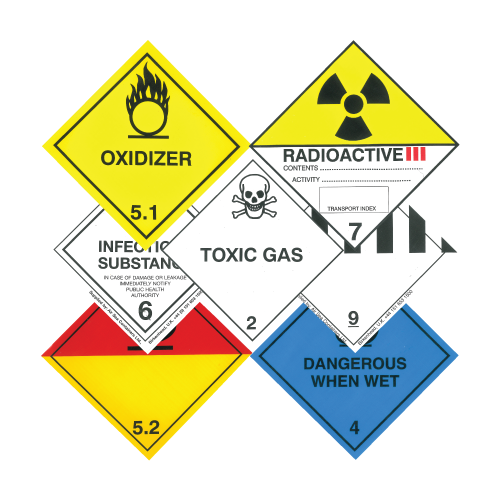

Additionally, correctly assembled UN approved packaging provides clear labelling and marking, helping handlers identify the nature of the contents and the potential hazards they pose. This information is crucial for emergency responders in case of accidents or spills, enabling them to take appropriate action quickly and effectively.

What is the difference between Single and Combination Packaging?

Single Packaging are packagings that do not require any inner packaging in order to perform their containment function during transport, an example would be UN approved Steel Drums or UN approved Jerricans. It is worth noting that single packaging can be used as an inner or an outer to form combination packaging if combination packaging is required for the dangerous goods wanting to be shipped.

Combination Packaging is as it says, a combination of packaging for transport purposes. Combination packaging consist of one or more ‘inner packaging’ for example glass bottles which are then secured in an ‘outer packaging’ for example a UN approved fibreboard box, the packaging chosen must be in accordance with the provisions set out in the relevant transport regulations.

Understanding the different types of UN approved packaging available

UN Approved Drums

Drums are a popular choice for UN approved packaging. They can be made from various materials such as fibreboard, composite, plastic, plywood, steel and other metals and are suitable for a wide range of hazardous materials, including liquids and solids. Drums come in various sizes and capacities, allowing you to choose the most appropriate option for your specific needs.

Steel drums are known for their strength and durability, making them ideal for heavy-duty applications. Plastic drums, on the other hand, are lightweight so can be cheaper in transport costs. If the substances being transporting are commonly known to erode steel, a plastic drum may be more suitable. It is the shipper’s responsibility to check with the regulation and the safety data sheet to see if their substance is compatible with the material type of the UN container.

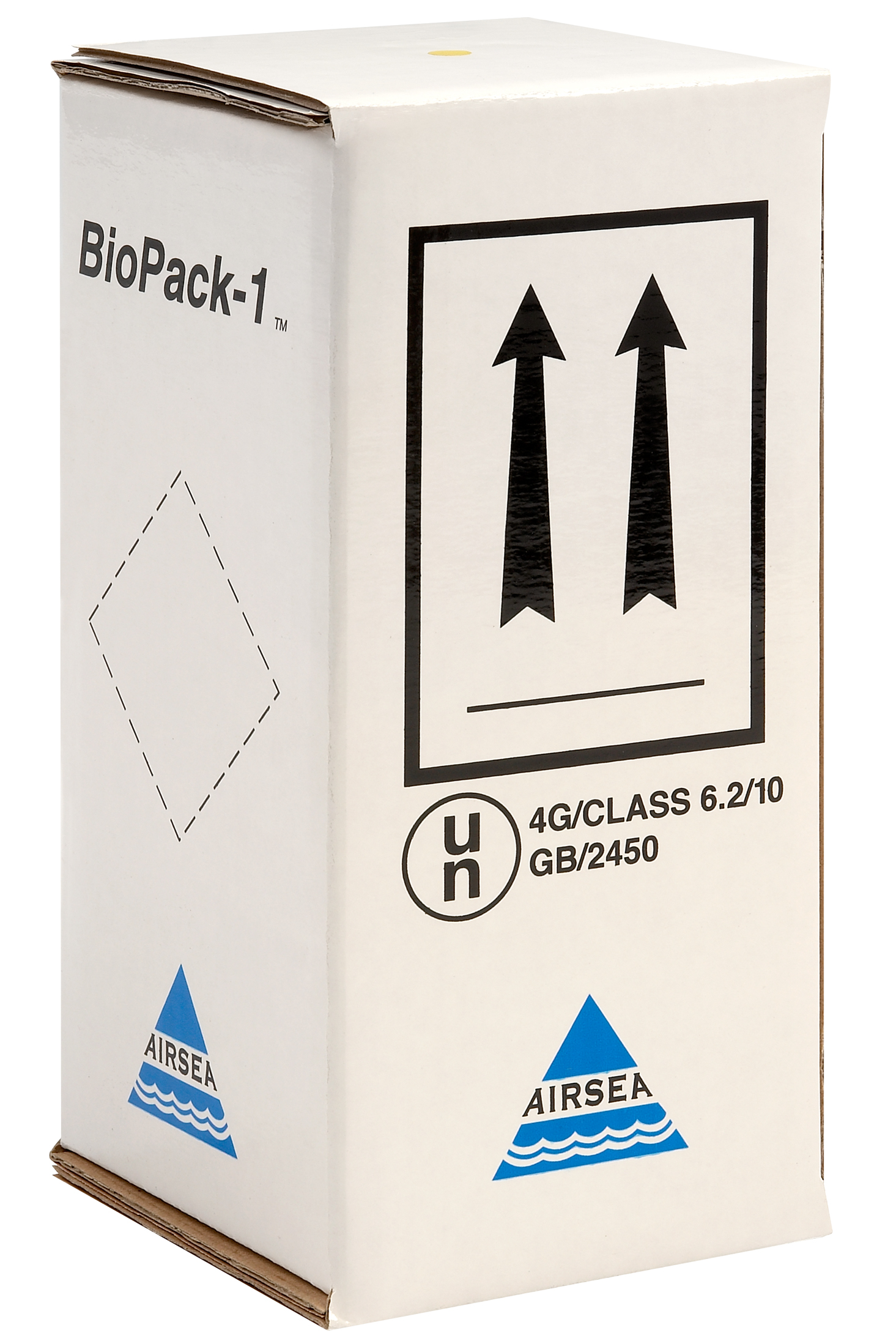

All UN approved drums undergo rigorous testing to meet UN regulations. This testing includes performance evaluations such as drop tests and stack tests. Drums that pass the specific tests detailed in the relevant mode of transport regulations are assigned a UN specification mark which provides information about the packaging type and performance tests that have been met, as well as their suitability for liquids or solids. The marks do not always provide full details of test levels met; these can be checked by referring to the test certificate.

Drums can be used as an inner to form combination packaging (e.g. a drum in a UN approved fibreboard box) however when using alone (single packaging) the drum can only contain suitable dangerous goods if the drum has been UN approved and displays a UN Specification Mark meaning it is suitable to be used as single packaging (no requirement for additional outer packaging).

UN Approved Jerricans

Un approved jerricans are another commonly used type of single packaging. They are typically made of high-density polyethylene (HDPE) plastic or steel/tinplate and are designed to safely transport hazardous goods (typically liquids). Jerricans come in various sizes, allowing for easy handling and storage.

One of the main advantages of UN approved jerricans is their compatibility with many chemicals. HDPE is known for its resistance to a wide range of substances, including types of acids, alkalis and solvents. Stainless steel for fuel, oils, solvents, foodstuffs and chemicals. This makes UN jerricans suitable for transporting a variety of hazardous liquids. As with all UN packaging, the shipper must ensure compatibility between the substance and the packaging material.

Like UN drums, UN jerricans undergo rigorous testing to ensure compliance with UN regulations. This includes tests for leakage, drop tests and stack tests. Jerricans that pass these tests are assigned a UN mark that provides information about the packaging type and performance tests that have been met and their suitability for liquids or solids. As with drums, jerricans can be used as an inner to form combination packaging (e.g. a jerrican in a UN approved fibreboard box).

Additional types of single packaging include; UN plastic and aluminium bottles, UN fibreboard drums and UN tinplate containers.

UN Approved Composite packaging

UN approved composite packaging consists of an outer packaging and an inner receptacle who’s construction forms an integral packaging creating a single unit. A composite drum is a combination of different materials, such as plastic and metal. It is commonly used for shipping liquids, powders and solids that require additional strength and durability.

The combination of different materials in composite packaging offers benefits such as increased resistance to punctures, impacts, and moisture. This makes it suitable for hazardous materials that may be sensitive to external conditions or require additional protection during transportation.

Composite packaging undergoes rigorous testing to ensure compliance with the UN regulations. This includes tests for leakage, drop tests and stack tests. Composite packaging that passes these UN tests is assigned a UN mark that indicates the packaging type and performance tests that have been met.

Again, composite packaging with a UN mark is a single packaging – a packaging that does not require any inner packaging in order to perform its containment function during transport.

UN Approved Fibreboard Boxes

UN Fibreboard Boxes are a versatile type of UN approved packaging that can be used for a wide range of dangerous goods. They are typically made of corrugated fibreboard and unlike single packaging, they are designed to be used as combination packaging with the use of suitable inners including glass and plastic bottles, jerricans or drums.

One of the key features of fibreboard boxes is their ability to provide excellent protection for fragile or delicate items. The corrugated structure of the fibreboard acts as a shock absorber alongside any additional required cushioning or absorbent materials, minimizing the risk of damage and leakage during transportation. Cushioning and absorbent materials for fibreboard boxes can include partition boards, foam, packing chips, vermiculite and moulds. Suitable cushioning and absorbent materials are determined at the testing stage of the fibreboard box and must be used going forward in order for the box to perform to its capabilities it has been tested and approved for.

These tests include drop tests and stacking tests. Boxes that pass these tests are assigned a UN Mark.

UN Approved Plywood boxes

Like fibreboard boxes, UN approved plywood boxes are designed to be used as combination packaging with the appropriate cushioning and absorbent materials to support and protect the chosen inners. They offer a strong, rigid outer packaging for the shipment of dangerous goods and are a popular choice for shippers that ship delicate, large or heavy items that require additional strength and durability. They can be used as combination packaging for a wide range of hazardous materials with the use of inners and are also suitable for shipping articles such as lithium batteries in accordance with the test certificate and dangerous goods regulations.

Plywood boxes are often collapsible and come flat packed, in these instances they are cost effective for delivery charges; plywood boxes tend to be lighter than a traditional wooden box of the same size, reducing future shipping costs. Many are often assembled without nails for convenience.

The solid structure of plywood boxes offers benefits such as increased resistance to impacts, and stack pressures.

Again, to gain UN approval, plywood boxes undergo rigorous testing to ensure compliance with UN regulations. This includes tests drop and stack tests.

Limited Quantity Packaging

Limited Quantities are dangerous goods that, when presented in smaller quantities have a reduced risk of harm to people, animals, property or the environment. This reduced risk allows for limited quantity shipments to be sent without extensively approved UN packaging.

However, the packaging used must be capable of withstanding packaging tests as outlined in UN dangerous goods regulations for air.

Examples of limited quantity packaging material includes combination packaging using Fibreboard boxes and inners.

Choosing the right UN approved packaging for your needs

Selecting the appropriate UN approved packaging for shipping dangerous goods is crucial to ensure compliance with regulations and maintain the safety of your shipments. Understanding the different types of UN approved packaging and their features, as well as its compatibility with the substance/article is essential in making an informed decision.

Whether you are shipping liquids, solids, powders or articles, there is an UN approved packaging solution that will meet your specific needs. From drums and jerricans to boxes, each type of UN packaging offers unique benefits and is rigorously tested to ensure compliance with the UN regulations.

By choosing the right UN approved packaging, you can minimize the risk of accidents, spills and contamination during transportation, protecting both the individuals involved and the environment. So, take the time to evaluate your shipping requirements by reading the correct mode of transport regulations and select the appropriate UN approved packaging solution that will keep your dangerous goods secure and compliant.

Information is correct at the time of publishing 20/06/24

UK

UK