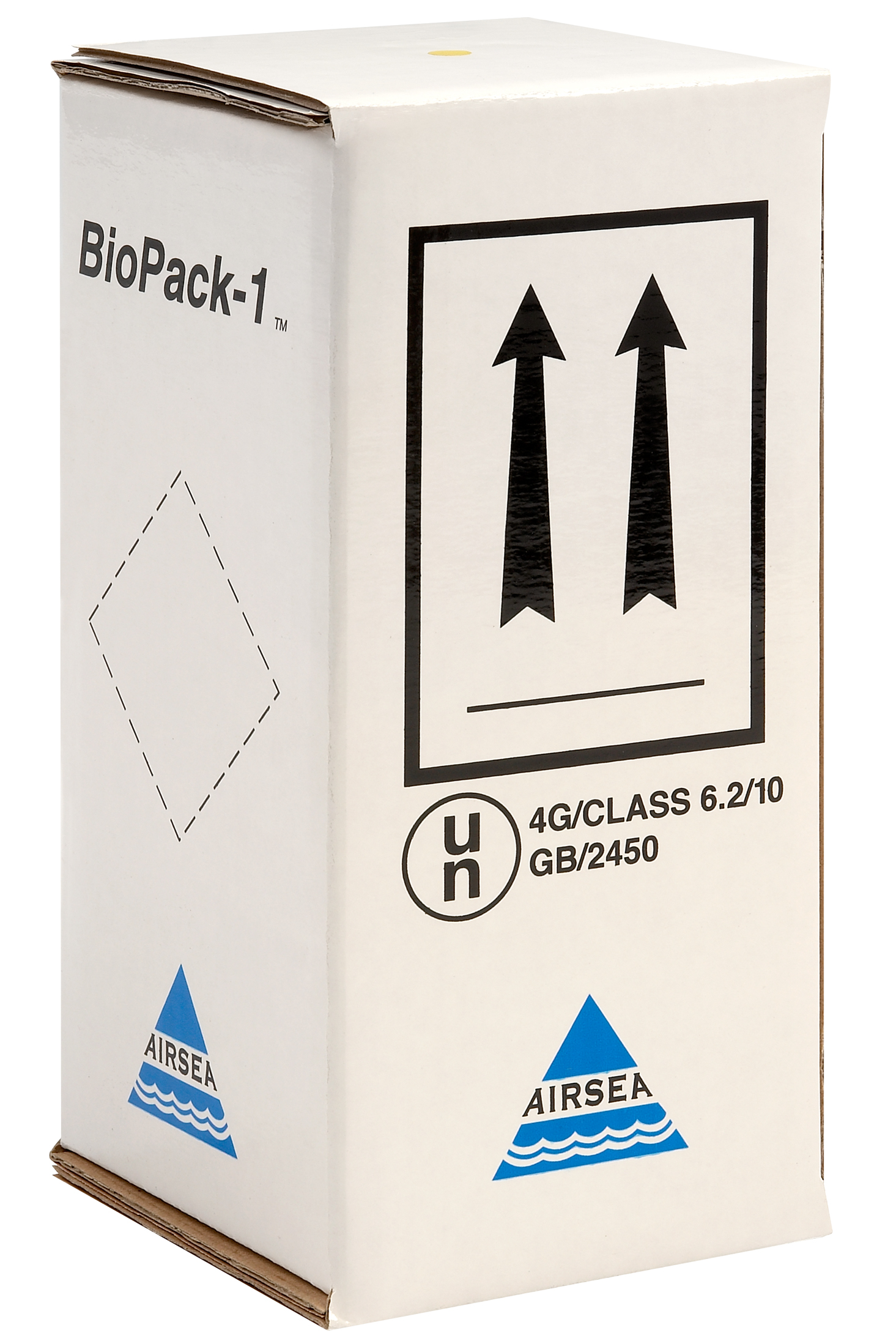

When shipping dangerous goods, both 4G and 4GV packaging are popular choices. Made of fibreboard, both provide good levels of protective support for dangerous goods when being shipped.

The packaging may look the same but there are subtle differences between the two which shippers may not be aware of. For example, there is often confusion about what inners can be used in a 4G box and what can be used in a 4GV box. We also get asked the question ‘how much dangerous goods can I put in my 4GV box?’

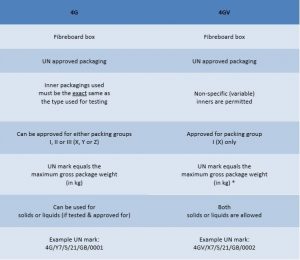

Comparison table

The below table provides a comparison of both packaging types and highlights a few of the main differences between the two.

The summary box above is not a comprehensive analysis but it does highlight 3 key areas of differentiation, here we discuss these in more detail.

4G Drop Tests and Packing Groups:

Where inner packaging is designed to carry liquids and solids, separate testing is required for both solid and liquid contents. For solids, if replacement substances are used in testing it must replicate the same physical characteristic of the intended substance. If another substance is to be used in the drop test for liquids it should be of similar relative density and viscosity to the substance to be transported.

Drop height for solids and liquids (liquids not exceeding relative density of 1.2):

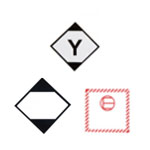

- Packaging for PG I (X) substances/articles = 1.8m drop test

- Packaging for PG II (Y) substances/articles = 1.2m drop test

- Packaging for PG III (Z) substances/articles = 0.8m drop test

As the 4G packaging has been specifically tested and approved for an individual packing group, the shipper must take note of the Packing Group stipulated within the UN specification mark and ensure they select 4G packaging that is suitable for the substance/article they wish to ship.

4GV Drop Tests, Packing Groups and Stacking test:

Because 4GV boxes allow non-specific variable inners, they are tested differently to 4G boxes.

Drop height for liquids (not exceeding relative density of 1.2):

- Packaging for PG I (X) substances/articles = 1.8m drop test

All 4GV packaging designs must be subject to a 1.8m drop test. That is because 4GV boxes have to be tested and approved to PG I (X) standards. As they are approved for the highest degree of danger PG I (X), it means they can also be used for substances/articles of a lesser degree of danger packing groups II (Y) & III (Z). This is of course providing the substance/article is permitted to be shipped inside the 4GV packaging.

Glass bottles containing liquids must be used as the inner packaging type during the drop tests for 4GV boxes.

Stacking tests for 4GV packaging designs stipulate that the outer packaging must be empty while undertaking the stacking test.

Inner Packaging

4G boxes can only be used to ship specific inner packagings – the same type that were approved at test stage, such as a specific Winchester bottle or a particular HDPE plastic bottle. The packaging supplier should be able to tell you which inners are approved for the 4G packaging in question and whether the complete package design is approved to hold solids or liquids or both. It’s worth noting that different inner packaging than those originally tested can be added to the UN approval, subject to verification by the testing authority. Depending on the difference in specification, the packaging certificate holder may be offered a deviation from a full test with reduced package testing such as limited drop tests.

4GV packaging, on the other hand, permit non-specific inner packaging allowing different inners from those tested. Meaning you can choose the most suitable inner for your substance, ie. glass bottles, plastic bottles, jerricans, drums etc.

Class 1 and 7 substances/articles are subject to specific restrictions and criteria. Any shippers wishing to use fibreboard packaging for class 1 and 7 should seek additional consultation from the Dangerous Goods Packaging supplier.

Weight Limits

For 4G packaging the approved weight specified on the UN mark is the maximum gross weight of the entire fully assembled package, this includes inners and contents, cushioning, packaging accessories and the outer packaging itself.

4GV weight limits are different as 4GV allows for various non-specific inners, the permitted gross mass of inner packagings including substances shall not exceed one-half the gross mass of inner packaging used for the drop test. For instance, if the packaging was tested with 10kg of inner packagings (inner(s) & substance), then the approved (permitted) gross weight of inners would be 5kg. The remainder of the gross package weight allows for the weight associated with the cushioning and packaging accessories as well as the outer box itself.

For more in-depth information on testing regime, packaging specifications or bespoke requirements contact us.

Information correct at time of publishing, 22nd June 2021

UK

UK