There are a number of different tape configurations you can use when securing packaging but which one is best for your particular UN Approved box? Surely you can just choose your preferred method and tape?

The simple answer is, no you can’t.

With UN Approved Dangerous Goods Packaging, all packaging will have gone through rigorous package testing to ensure the package can withstand ‘normal conditions of transport’.

In order for the package to perform as it did during the package testing, when using the UN approved packaging it must be assembled and the article/substance packed in the exact same way the packaging was tested for. UN approved packaging assembled incorrectly will invalidate the performance certification. This includes the type of tape and the taping method that was used to seal the box during testing.

So, you must always refer to the manufacturers assembly sheet and assemble the box exactly as instructed.

The assembly sheet should be provided when you purchased the box, as that will inform you of how the box needs to be assembled, packed and sealed. For example, the type and width of tape to use, the taping method, some boxes may require you to add two layers of tape, others have pre-printed numbers on the box flaps and require you to fold them in a specific order. Whatever the requirement is, it will be documented on the assembly sheet.

If you don’t get an assembly sheet with your packaging you should go back to your supplier and request one, otherwise if incorrectly assembled you risk invalidating the performance certification.

It is worth noting that for consistency, even though not UN Approved, LQ, EQ and Category B packaging should have a recommended sealing method. So always check with your supplier whether the packaging has assembly instructions.

Here we explain the two typical taping methods used.

H shape tape method

- Seal the bottom of the box first. Fold the smaller box flaps in then the two larger flaps. If the box is square, fold two opposing end flaps in, then the other remaining two flaps and tape as per the method below.

- For ease, use a tape dispenser. Apply the tape to adjoin the bottom folded flaps sealing the entire length of the join. Make sure you allow overhang on both sides of the box to ensure a secure seal.

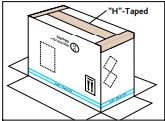

- Tape both ends of the box that have an opening along the bottom of the box edge. You will now have a secure seal and will be able to see how the shape of the tape looks like a ‘H’. (See Figure 1)

- Once you have filled the box with the appropriate contents, repeat steps 1 to 3 on the top of the box. (See Figure 2)

Figure: 1 Figure: 2

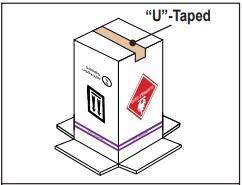

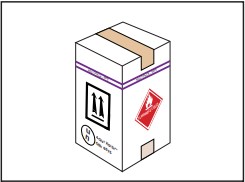

U shape tape method

- Seal the bottom of the box first. Fold the smaller box flaps in then the two larger flaps. If the box is square, fold two opposing end flaps in first then the other remaining two flaps and tape as per the method below.

- For ease, use a tape dispenser. Apply the tape to adjoin the bottom folded flaps sealing the entire length of the join. Make sure you allow overhang on both sides of the box to ensure a secure seal.

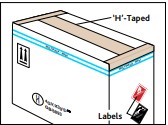

- You will now have a secure seal and will be able to see how the shape of the tape looks like a ‘U’. (See Figure 3)

- Once you have filled the box with the appropriate contents, repeat steps 1 and 2 on the top of the box. (See Figure 4)

Figure 3 Figure 4

If you would like advice on the correct taping method for any of our UN Approved Boxes, get in touch.

Information correct at time of publishing, 9th March 2021

UK

UK