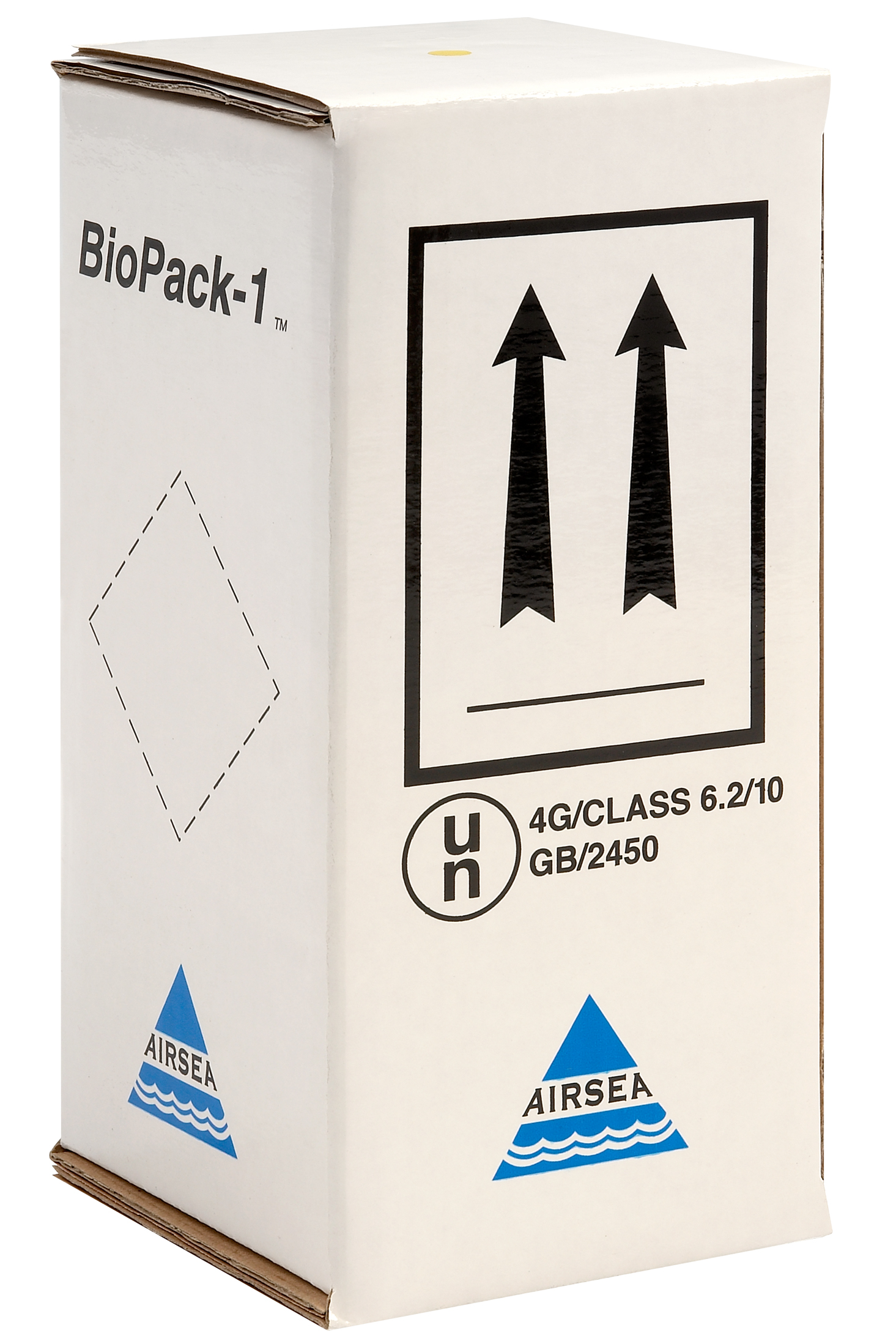

UN Approved Outer Packaging for Dangerous Goods

What is outer packaging? Outer packaging simply put is the outer protection of a composite or combination packaging. Placed inside the outer packaging would be the inner receptacles or inner packaging for example glass bottles, as well as any absorbent or cushioning material needed to contain and protect the inner(s). When fully assembled (the outer, inner and accessories) this is referred to as combination packaging.

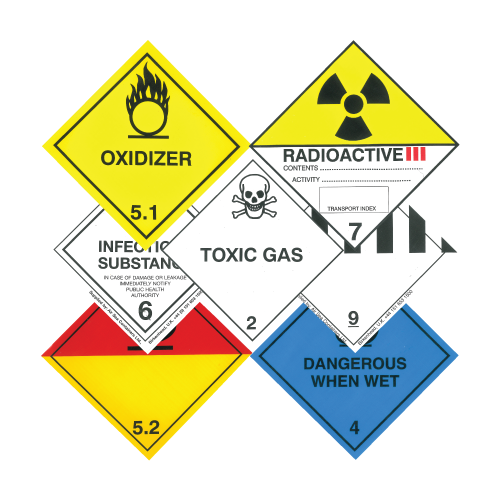

There are various dangerous goods outer packaging materials and types available. At Air Sea Containers we have a range of UN Approved Outer Packaging, 4G, 4GV & 4DV, our inners can be found on our Inner Packaging page.

Our 4G fibreboard outer packaging range are robust fibreboard boxes which have been tested with the use of specific inners. The 4G outer packagings have therefore been certified to be used with the tested inners only. You can also use some of our specific outer packaging for liquids. There is a complete list of all approved inners on the specific 4G product page.

Weight allowance explained. Our 4G outer packaging weight allowance is stipulated on the UN box within the UN Mark, this is the gross package weight, meaning your inners, accessories and the weight of the fibreboard box must not be more than the weight stipulated on the UN box.

Each of the products in our 4G range come with assembly instructions to guide you through the packing process. The 4G packaging must be packed and assembled in the same way as it was during the testing process, otherwise you will invalidate the UN certification.

Our 4GV fibreboard outer packaging range are again robust fibreboard boxes, yet, these can be used with ‘non-specific inner containers’, meaning you are free to choose your preferred suitable inner for use in the 4GV outer packaging in accordance to the relevant transport regulations.

Again, as with the 4G range, the printed weight on the 4GV fibreboard box is the gross package weight, there are additional weight stipulations relating to the maximum weight of contents (product and containers) allowed in the 4GV outer package. For ease, we have stipulated the gross weight allowance and the content weight allowance on each of the individual product pages.

To make it even easier, we have produced assembly sheets for each of the 4GV boxes which you can download from the product page. These stipulate weights and assembly instructions for packaging the dangerous goods compliantly. The 4GV packaging must be packed and assembled in the same way as it was during the testing process, otherwise you will invalidate the UN certification.

Our 4DV plywood outer packaging allows you to ship up to a maximum gross weight of 280Kg. Like our 4GV range, when using our 4DV plywood UN boxes as your chosen outer packaging, you can choose the most suitable inner for your substance in accordance with dangerous goods regulations applicable for your chosen mode(s) of transportation.

The printed weight on the 4DV Plywood box is the gross package weight, there is also a maximum weight of contents (product and containers) allowed in the outer package. You can find the gross weight allowance and the content weight allowance on each of the 4DV product pages and the assembly sheet.

UK

UK